Exploring the world of fiber cement panel siding, this introduction sets the stage for a deep dive into the process of installation. From its durability to common applications, this overview will equip you with the knowledge needed for a successful siding project.

As we navigate through the tools required, preparation steps, installation techniques, and finishing touches, you'll gain a thorough understanding of how to effectively install fiber cement panel siding.

Introduction to Fiber Cement Panel Siding

Fiber cement panel siding is a versatile building material made from a combination of cement, sand, and cellulose fibers. It is known for its durability, low maintenance requirements, and aesthetic appeal.

Advantages of Fiber Cement Panel Siding

- Excellent durability, able to withstand harsh weather conditions and resist rotting, warping, and cracking.

- Low maintenance, requiring only occasional cleaning to maintain its appearance.

- Fire-resistant properties, adding an extra layer of safety to buildings.

Common Applications of Fiber Cement Panel Siding

Fiber cement panel siding is commonly used in residential and commercial construction projects for:

- Exterior cladding

- Soffits and fascia

- Trim details

- Interior wall panels

Tools and Materials Required for Installation

Installing fiber cement panel siding requires a specific set of tools and materials to ensure a successful and efficient installation process. These tools are essential for cutting, fastening, and sealing the siding panels securely to the exterior of a building.

Tools Required:

- Circular Saw: used for cutting the fiber cement panels to the desired size and shape.

- Jigsaw: necessary for cutting curves and intricate patterns on the siding panels.

- Utility Knife: for scoring and cutting the panels during installation.

- Caulk Gun: to apply sealant around windows, doors, and corners for weatherproofing.

- Tape Measure: essential for accurate measurement and cutting of the siding panels.

- Siding Nailer: to fasten the panels securely to the exterior wall.

- Ladder: for reaching higher areas of the building during installation.

Materials Required:

- Fiber Cement Panels: the main material for the siding installation, providing durability and weather resistance.

- Fasteners: such as nails or screws, to securely attach the panels to the wall.

- Sealant: to seal gaps and joints between panels, preventing water infiltration.

- Flashing: to protect vulnerable areas like corners and edges from moisture.

- Paint or Primer: for finishing the siding panels and enhancing their appearance.

Preparing the Installation Area

Before installing fiber cement panel siding, it is crucial to properly prepare the area to ensure a successful and long-lasting installation. This includes creating a clean and level surface, as well as addressing any existing issues like moisture or mold.

Cleaning and Leveling the Surface

- Begin by thoroughly cleaning the area where the siding will be installed. Remove any dirt, debris, or old siding to create a smooth surface.

- Inspect the wall for any protrusions or imperfections that could affect the installation. Use a level to ensure the surface is straight and even.

- Make any necessary repairs or adjustments to the wall to create a flat and stable foundation for the siding.

Addressing Moisture and Mold Issues

- Check for any signs of moisture or mold on the wall where the siding will be installed. These issues can compromise the installation and the longevity of the siding.

- If moisture is present, identify and fix the source of the problem before proceeding with the installation. This may involve repairing leaks or improving ventilation in the area.

- To address mold, clean the affected area with a solution of water and bleach to kill the mold spores. Ensure the wall is completely dry before installing the siding.

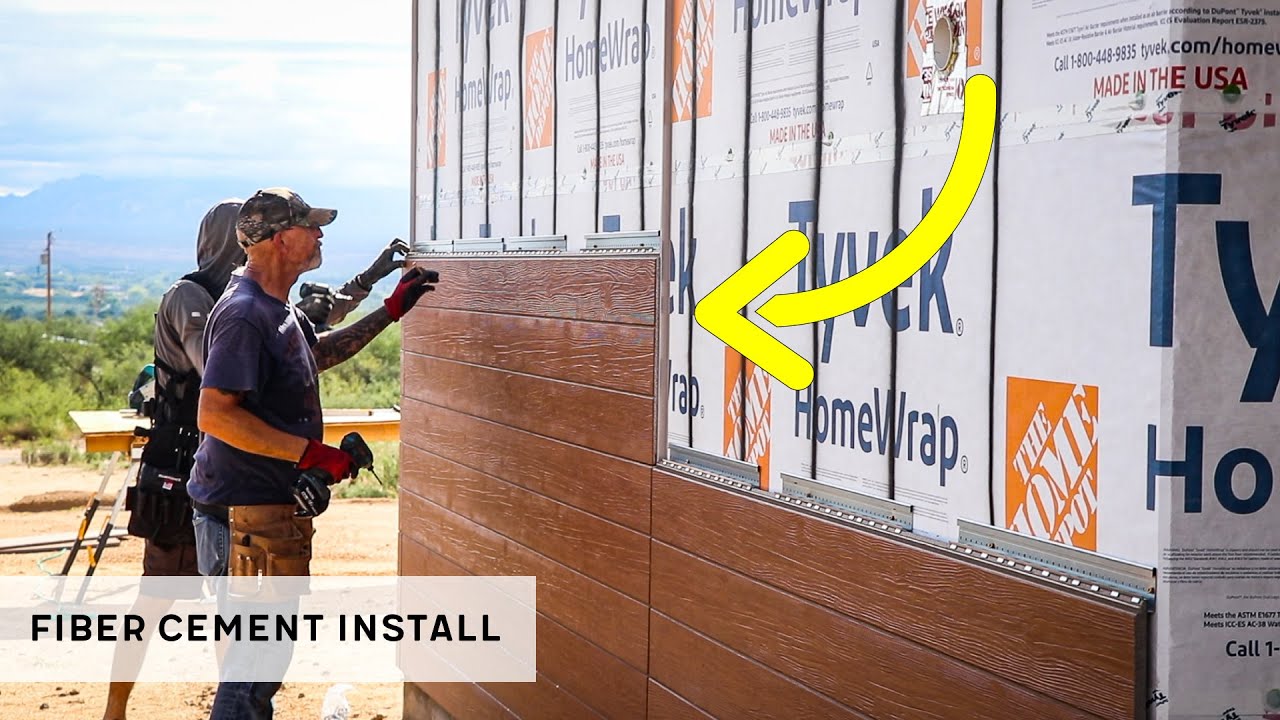

Installing Fiber Cement Panel Siding

Installing fiber cement panel siding is a crucial step in the process of enhancing the exterior of your home. Proper installation ensures durability and a visually appealing finish. Below is a step-by-step guide on how to install fiber cement panel siding, including techniques for cutting and fitting the panels, as well as securing them to the structure with the correct fasteners.

Step-by-Step Installation Guide

- Start by measuring the area where the siding will be installed and cut the panels to fit using a circular saw equipped with a carbide-tipped blade.

- Ensure that the panels are properly aligned and leveled before attaching them to the structure.

- Use corrosion-resistant nails or screws to secure the panels to the studs or sheathing, following the manufacturer's recommendations for spacing.

- Overlap the panels by the recommended amount to allow for expansion and contraction due to temperature changes.

- Continue installing the panels in a staggered pattern until the entire area is covered, making sure to leave space for corner trims and other accessories.

Cutting and Fitting Techniques

- When cutting fiber cement panels, use a straight edge and a carbide-tipped scoring knife to create a clean and precise cut.

- For curved cuts or more intricate shapes, a jigsaw with a carbide-grit blade can be used to ensure accurate fitting.

- Test fit each panel before securing it in place to ensure a proper fit and alignment with adjacent panels.

Securing Panels with Fasteners

- Choose the appropriate fasteners based on the manufacturer's recommendations, typically galvanized or stainless steel nails or screws.

- Fasten the panels at the recommended spacing along the studs or sheathing, ensuring a secure attachment that allows for movement.

- Avoid overdriving the fasteners to prevent damage to the panels, but make sure they are driven flush with the surface for a neat finish.

Sealing and Finishing

After installing fiber cement panel siding, it is crucial to seal it properly to protect it from moisture, UV rays, and other elements that could cause damage over time. By sealing the siding, you can enhance its longevity and maintain its appearance for years to come.

Types of Sealants

- Acrylic Sealants: These sealants are flexible and easy to apply, ideal for filling gaps and joints in fiber cement siding.

- Silicone Sealants: Known for their waterproof properties, silicone sealants are great for areas prone to water exposure.

- Polyurethane Sealants: Offering excellent durability and weather resistance, polyurethane sealants are a popular choice for sealing fiber cement siding.

Finishing Touches

- Caulking: Use a high-quality caulking material to seal any gaps or joints in the siding for a seamless look and added protection.

- Painting: Apply a coat of paint to the fiber cement panel siding to enhance its appearance and provide an extra layer of protection against the elements.

- Cleaning: Regularly clean the siding with a mild detergent and water to remove dirt, grime, and stains that could affect its longevity.

Last Word

In conclusion, installing fiber cement panel siding is a meticulous yet rewarding task that can greatly enhance the aesthetics and durability of any structure. By following the steps Artikeld in this guide, you'll be well-equipped to tackle this project with confidence and precision.

Essential Questionnaire

What are the advantages of fiber cement panel siding?

Fiber cement panel siding is known for its durability, low maintenance, and resistance to fire, insects, and rot.

What tools are needed for installing fiber cement panel siding?

The tools required include a circular saw, utility knife, caulking gun, tape measure, and a hammer.

How important is it to seal fiber cement panel siding?

Sealing fiber cement panel siding is crucial to protect it from moisture and prolong its lifespan.